Blog

Now that the carbon fibering of the inside of ThunderDawg was complete, the team cut out the outside of the prototype vehicle in late January. Midway through cutting out the body, the electricity in the building went out. After much effort and concentration, we re-zeroed the foam router almost perfectly and finished cutting out the body. Despite the complications due to the power outage, the cut came out quite...

After finishing cutting out the inside of the ThunderDawg body on the foam router, the prototype vehicle was carbon fibered. The process of carbon fibering the inside of the prototype vehicle was very tedious because of the curves of the body, but everything turned out quite well!

Here is a picture of the status of the two new vehicles as of January 21st. On the left is the carbon fibered body of HotRod and on the right is the finished cut for the inside of ThunderDawg. It is so great to see both of our cars making progress!

Now that the carbon fibering of the outside of HotRod was complete, the team began sanding the body. Seen in the picture are two of our team members sanding HotRod.

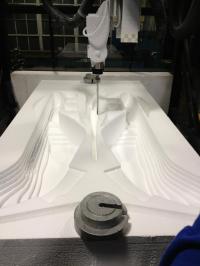

In mid January, the prototype vehicle’s design had been finalized. We used the foam router to cut out the inside of the ThunderDawg body. The cut turned out wonderful and was then ready to carbon fiber! The picture shows the foam router at work cutting out the inside of ThunderDawg.

| Louisiana Tech University

| Louisiana Tech University